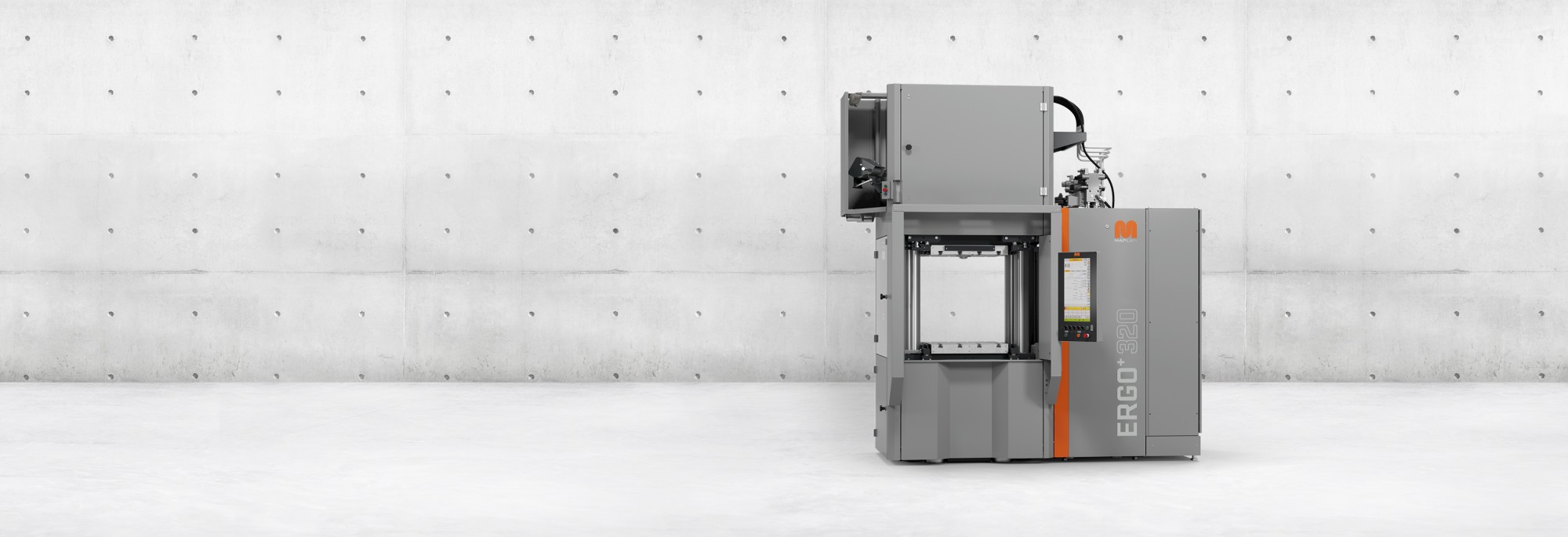

Precise & Versatile – the vertical MAPLAN ERGO+ injection moulding machines are designed to suit a variety of requirements and impress with their high quality and optimised repeat accuracy. The entire ERGO+ series comes equipped with the energy-saving servo-hydraulic MAP.cooldrive and the high-precision MAP.fifo injection unit.

MAPLAN VERTICAL

ERGO+

Ergonomics across the board

Advanced. Features.

Highlights

- Ergonomic operating height

- Compact machine design cast in one pour

- High flexibility for efficient automation and tailor-made customer solutions

- Cold runner ready

- Comes with all MAPLAN+ benefits

Models

| TYPES | CLAMPING FORCE | INJECTION VOLUME | HEATING PLATE DIMENSION | |

|---|---|---|---|---|

| [kN] | [cm³] | Standard [mm] | Maximum [mm] | |

| ERGO+ 90 | 900 | 200 – 1000 | 300 x 400 | 380 x 450 |

| ERGO+ 160 / 180 | 1600 / 1800 | 200 – 2600 | 450 x 510 | 535 x 560 |

| ERGO+ 250 / 280 | 2500 / 2800 | 200 – 4000 | 560 x 650 | 670 x 650 |

| ERGO+ 250XL / 280XL | 2500 / 2800 | 200 – 4000 | 560 x 780 | 760 x 780 |

| ERGO+ 320 | 3200 | 200 – 4000 | 670 x 780 | 760 x 850 |

| ERGO+ 400 / 460 | 4000 / 4600 | 1500 – 8500 | 710 x 800 | 800 x 810 |

Fr the fully automatic production of articles for:

Automotive industry, household and white goods, sanitation, oil production, medical technology, railways, electrical engineering, alternative energy and custom-made products.

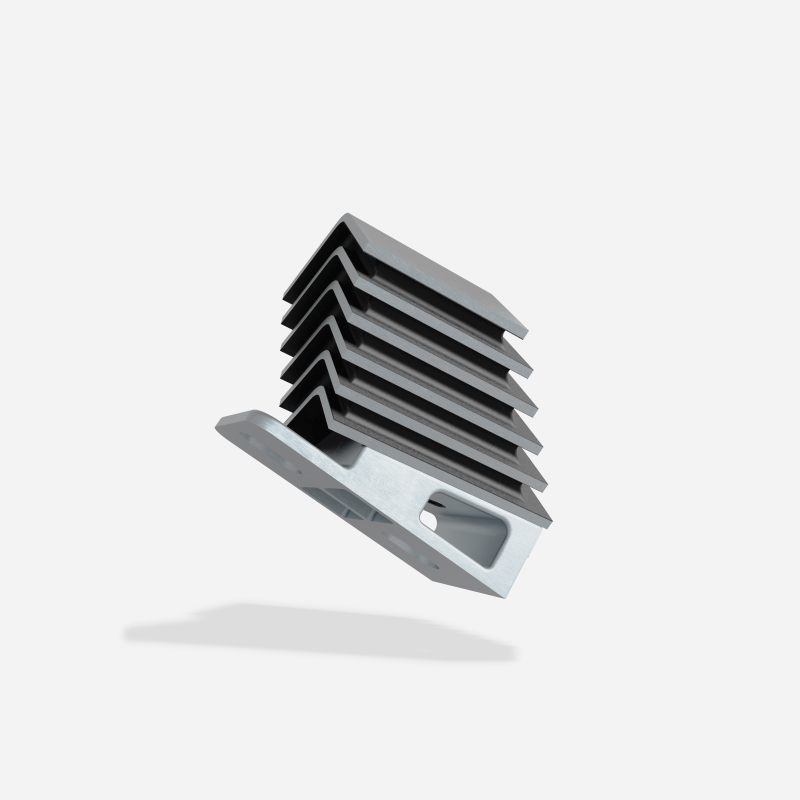

Typically produced with ERGO+:

Rubber-metal parts / inserts